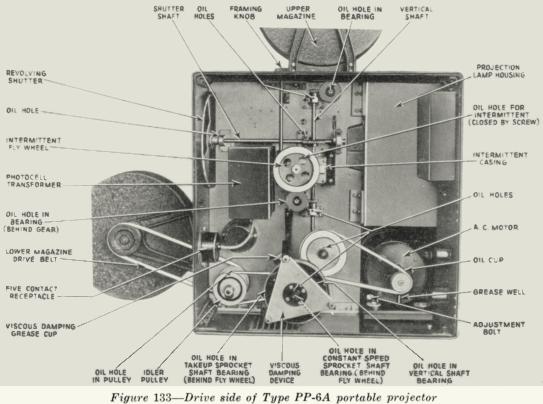

274. Lubrication of Projector. -The necessary lubrication of the projector is quite simple and is easily

done. The necessary points of lubrication can be classified under four headings:-the motor, the

intermittent, the shaft bearings, and miscellaneous parts. Use a good grade of light machine oil except

where otherwise noted.

The motor is provided with two oil cups and two oil wells, as illustrated. Two or three drops of light

machine oil for each week's use is sufficient. The oil wells should be refilled with fresh vaseline every

month or two, depending on the amount of use to which the projector is submitted.

The intermittent is lubricated through an oil hole in the top of its casing. The intermittent should be

kept supplied with light machine oil so that the level in the

casing about covers the window located in the side of the intermittent casing. On some of the

projectors this oil hole is accessible by turning a knurled cap so as to make the hole in the cap coincide

with the hole in the tube on which it is mounted. On other projectors a round headed machine screw

must be removed for oiling. The oil holes should be kept closed to prevent loss of oil. Do not let the

intermittent mechanism run dry.

All shaft bearings illustrated in Figures 131, 133, 134 and 135 should receive a drop or two of light

machine oil for each show, or every two hours of continuous running. The impedance fly-wheel shaft

bearing should be lubricated with Three-in-One oil only. Use a few drops for each day's use. See Figure

134.

5